Search for the Protein Sequence

The Office of Naval Research awarded a three year grant to the team at Washington University to investigate ‘layered nano-structures’ like the abalone shell infamous for its strength and resilience. Clement Furlong supervisor to Rich Humbert and leader of Medical Genetics stated ‘Once we sequence the protein we’ll have to find a way to produce lots of it’1.

Collecting it is hard on the abalone population and scraping the muscle out of its shell then processing it truncates the protein molecules or worse. Alternatively the familiar E. coli bacteria could be employed to manufacture the protein. We have it in our own gut. It has been used by bacteria, yeast, mold for making wine, brewing beer, leavening bread and culturing cheese. Bacteria is grown in vats to produce food additives, antibiotics, industrial chemicals, vitamins and more.

- B1 Thiamin

- B2 Riboflavin

- B12 [anaemia] present in fish, meat, poultry, eggs. B6 present in pork, poultry, fish, bread, whole cereals, eggs.

Biotechnology

Insulin manufacture for example we take a human gene and splice it into E.coli. Then the E.coli-modified actually produces the insulin. In times gone tons of pork was processed to refine purified insulin2. Both hormone and protein, insulin is a sequence of 51 amino acids, differing from pork’s insulin in only one. By the 1970’s scientists were stringing together nucleic acids in arrangements to synthesize human genes including the insulin gene. A gene is a section of DNA with instructions to make a particular protein. Scientists inserted a synthesized gene into a small loop of a carrier DNA to guide the production of a protein.

The DNA ring needs to be inserted into an organism with the biological capabilities needed to assemble a protein. Researchers at Genetech announced in 1978 that they had a strain of E.coli bacteria produce the insulin protein by giving it a human gene2.

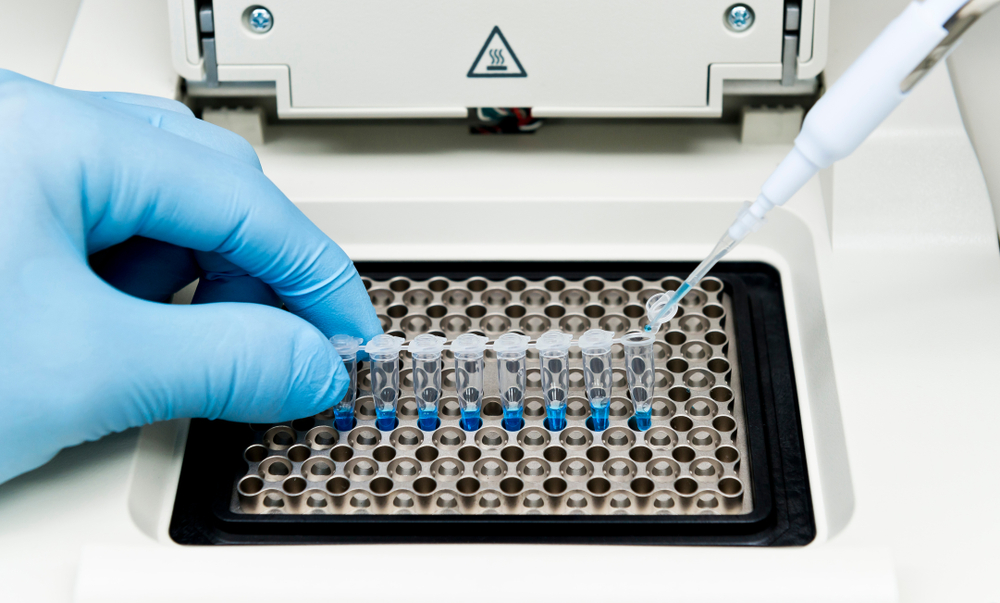

Once the protein is sequenced, the dip-and-coat procedure for making nacre (abalone). From the protein template they will insert that DNA into E.coli. Then hope the E,coli follows the coded instructions in the template DNA to produce proteins to order in a bio-reactor supplied with water, food and air.

Fishing for templates

A key discovery in molecular biology is the procedure to find the gene or portion of the gene that is responsible for producing the required protein. The code for the protein that templates crystalline production is in the abalone’s cell, in a DNA segment. Finding it is the key.

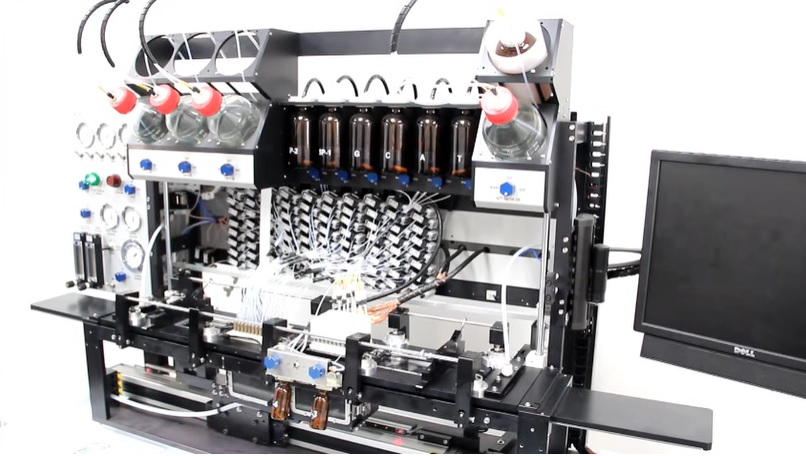

The OLIGIO machine

To get the protein with the code we need; a seeker code that keys into the desired code can be made using a machine that links together a sequence of nucleotide molecules which are the elements of a DNA code. The oligio machine drips the adenine [A], the thymine [T], the guanine [G] or the cytosine [C] onto the carbon based chain to produce the coded seeker protein which will attach to the protein chain needed, referred to as the complimentary DNA [cDNA]. Nucleotide A will compliment T, and nucleotide C will compliment G. So the seeker protein will attach to a cDNA on a much longer protein chain. Then hopefully the whole protein is intact and more hopefully a compliant strain of E.coli will take the cDNA and produce the protein needed for the form work for the crystal.

To determine whether the E,coli is producing the desired protein scientists use another biological probe – an antibody just like those produced by our immune system. Rather than inject ourselves with mollusk protein they use a rabbit to produce an antibody to attach and interfere with the mollusk protein. Instruments will identify where the antibodies are conglomerating. Then that cluster of E.coli can be distributed onto more dishes to grow their colonies of the desired protein.

The question arises will crystals grow as well on differing protein structures? Trial and testing will only answer that.

Using the natural method of growing crystals

Galen Stuckey of the department of Chemistry and Daniel Morse of the department of Molecular and Cellular Developmental Biology at the University of California found as the Washington team found that insoluble proteins congregated at the bottom of the beaker instead of going into solution and were not giving up their amino acid sequence. Stuckey and Morse determined they would make a protein analogue to stand in for the real abalone protein3.

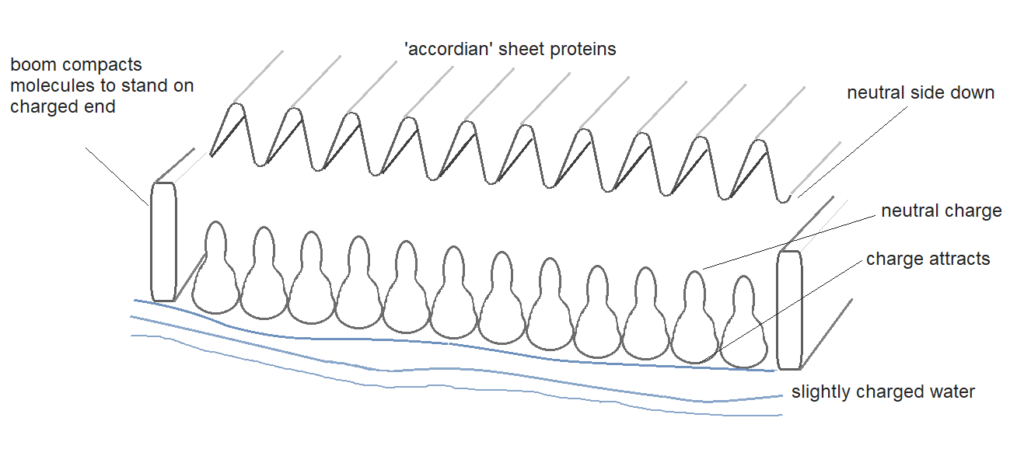

First job was to get the analogue protein to stick to a surface that could support crystal growth. They chose Langmuir – Blodgett film4.

With the aid of chemical, ‘hooks’ the protein sheet embeds into the fatty layer of B-L film. While negatively charged ‘pleats’ of the protein molecules hang down into the water creating landing sites for the ions of the crystal medium5.

Being able to arrange the placement of the nucleation sites Morse can basically direct what kind of crystal will grow crystals. Peter C. Rieke material scientist is trying to grow crystals on a thin film. Made in a laboratory, film called ‘self assemble monolayers (SAMS)6. Instead of being suspended on water they are coated onto glass slides. And the chemical charged groups are part of the film itself. The charge groups are positioned where they are functionally needed. The films are a mosaic of positive or negatively charged shapes that serve as landing sites for the ions from solution to attach and grow crystals.

Potentially different types of crystals could grow on the same film. The process is still two dimensional where as the mollusk’s build crystalline structures between the abalone’s body and its outer shell.

Rieke uses a polystyrene substrate, common plastic used for bottles and caps, it is a polymer analogous to the biopolymer the mollusks employ for nucleation. (More on nucleation see further reading) He has tried the old calcium carbonate, lead iodide, calcium iodate and iron oxide6. Application for crystalline structures are being considered for high specification components in vehicles, windows in lightweight electric cars, and coating for gearing where abrasion and corrosion resistant surface treatments are required. A two bath dipping process, first coat with the template protein the second the mineralized ionic crystal would revolutionize the coating technology from information storage to drive trains.

3D Crystal Containers

Stephen Mann biomineralization expert in Bath, England is creating three dimensional protein sheaths using balloon like shapes to mineralize small particles. Single celled magneototactic bacteria produce perfect crystals wrapped in organic membrane. An example of a magnetic presence in a chemical reactor without the magnets clumping together, neutralizing themselves7. Ferritin is the protein that sequesters iron oxide in the human body, which prevents rust being in our cells.

He has made organic balloons of various shapes and has used jelly like polymer that can be inserted with minerals giving the hardness quality with the flexibility of the polymer7.

Fabbers

3D printing using using computer aided design build up precise objects by adding cross-sectional layers one at a time. Paul Calvert is involved with developing ‘print heads’ that will deliver layers of differing materials or solutions, for example chalk and proteins. Composite materials could be incorporated in gradients to interlace joins making them stronger14.

High Tech Organics

Resiliant materials are created constantly in living organisms, skin, tendons, blood, cellulose, a variety of adhesives. Organic compounds are based on carbon chain molecules. Life forms make them to order and the form definitely follows their function. There is no by product or residual waste, native life cannot afford extraneous consumption or energy.

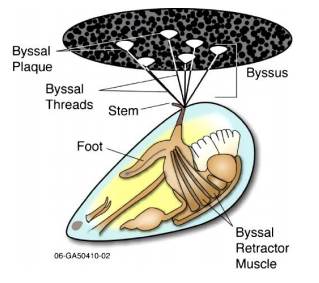

Herbert Waite’s research while affiliated with University of California, Santa Barbara worked with mussels (Mytilus edulis ). The only response available to the sessile mussel Mytilus edulis in order to avoid predators or desiccation during aerial exposure is valve closure. The posterior adductor muscle is able to remain contracted for several days at low energy cost9. If you had tried to take one you would notice how hard they are to remove from their chosen location. M. edulis’ attachment is made up of tethers called byssus with discs on their ends called plaques they use to locate themselves in the tidal zone8.

Engineers have determined that if you want something to stay put in a wave battered coast by itself it needs to be of the order of 40 tonne. The M.edulis sends out a flesh tongue like extremity and creates a thread and plaque with adhesive tether called ‘byssus complex’. Glands secrete collagen protein (as in tendons) into a groove in the tongue that acts as a mold. The thread and plaque self assemble and harden in the groove and then a gland near the tip of the tongue squirts adhesive protein between the plaque and the surface of its residential site8. A few minutes is all it needs. The bi-valve can repeat the tethering to oppose the wave pressure. Then it can open its shell to allow filtering of the turbulent sea water to extract nutrients13. M.edulis produces an adhesive that can be applied in brine and bonds extremely well to any surface. Pushing its tongue onto the surface squeezing out water it then deposits a mucus seal around the edges of contact. Next the muscles in the tongue pull off the contact zone to form a cavity with partial vacuum (like a bell shaped suction cup). The thread and disc are cast then adhere to the surface10.

We would make separate parts as we perceived the functions required and us an applicable glue (polymer sealant probably) to stick them on. The bi-valve now manufactures the solid foam disc (plaque) that is formed in the grooved mold from different proteins that squirt out of the cavity. It thickens to foam (like Styrofoam) which suits the characteristics a mussel would want in its foot (byssus), flexible and fracture resistant8.

The thread of M.edulis’ byssus is similar to our manufactured polymer entwined cord. Single fibres twisted or woven together to share a load on the whole cord, rope or cable. Herbert Waite when studying the byssus found not one collagen based protein but hundreds all slightly different in composition. Along the collagen chain each molecule has a section that is springy (like a tendon) and another section more rigid (like skin). The proportion of rigidity to spring depends on where the molecule is situated along the byssus thread. The molecular selection arrangement of M.edulis makes its byssus have more capacity in its properties than mono-molecular collagen10.

Modern manufacturing is riddled with fasteners, screws, bolts, rivets, anchors, ties and adhesives. Nature ‘blends gradients so that the fiber has no single vulnerable point’ Paul Calvert would say14.

The byssus of the mussel is like grissle but still food (protein) for any organism with voracious appetite. Fully aware of this M.edulis applies a clear sealant of yet another protein this time impervious to microbes. But not permanently so, the mussel will move on at will leaving its byssus. The protein sealant will breakdown in two to three years allowing the microbes to devour the protein morsel11,12. Again nature’s mussel waste is used. Our present petrochemical plastics are relatively indestructible. Yet they break into small chips and particles in sun light, yet they remain indigestible by organisms.

Plastic containers will remain in landfill and contaminate most habitats long after we have decayed. Consumer products that only need a short life cycle could be made from naturally grown materials like cellulose, silk, collagen, rubber or chitin (as in crab shells) and seal them with a resilient coating that does breakdown to digestible condition for microbes in land fill to consume and return the material to the food cycle.

The adhesive exuded by M.edulis has protein chains with molecular hooks that Velcro-like link onto similar molecules. The integrity of the molecular cross linking is fully achieved with the aid of a catalyst specific for that purpose. Just to recap the lowly mussel M.edulis forms its own fibre, plaque, adhesive and sealant.

Companies are chopping up mussels, purifying the protein and using the mollusk’s protein to coat glass slides as a cell and tissue adhesive. I am reminded of the pearl diving industry of the Red Sea. Five hundred clams were collected and prized open for every natural (grit irritant) pearl collected. The mussel is a filter feeder so has little control about what it ingests. The same protein that forms the adhesive that glues its byssus to metal or rock or painted surfaces also adheres to the heavy metal particles M.edulis takes in. So when it leaves a site it leaves the byssus with its metal toxins behind.

We have the silk worm, cotton, wool for textiles, thread and yarn. And then there is spider web filament (silk) once used for drawing open flesh wounds to gather the skin lesions. Silk is collected by boiling the cocoon with the silk worm grub (pupae) inside to unravel the filament strands. Do we have factories of spiders fed on insects to issue extrusions of their super thread? They could deliver 30 meters at one shift.

“Ambushing its prey whilst dangling from its complex web of super strength and invisible death”

The golden orb weaver (Nephila clavipes) produces six fibers (silks) each each concocted in its own gland extruded through an individual spinneret15. Spiders perform various functions with their silk18; radiating webs with fine silks coated with glue, dense sticky sheets, invisible snares, a single strand with adhesive ball slung at its prey. Males impregnate pheromones onto their silks; some wrap the silk with sperm to be fertilized by the female, notorious for attacking their suitor and wrapping him into a silk sarcophagus. Some males impregnate their silk with an immobilizing agent16.

In some conditions inorganic materials will orderly combine with organic materials to form a rigid crystalline structure. In liquid state molecules will align in orientation but be fre to move location that can be called liquid crystal. An indication of crystal form in a material is its refractive index (R.I.). The RI of silk 17 is known but for spider silk it is much higher. The spider has the ability to combine different material types into one composite.

Spider silk has properties far exceeding those of steel, weight for weight five times the tensile strength. And five times the impact resistance of Kevlar as well as being more elastic than nylon (more on the unintended effects of Kevlar in Further reading). It also resist freezing becoming rigid so being less likely to break. Spider silk starts out at as liquid protein in a gland sack, water soluble before it is extruded through one of its 6 groups of nozzles (spinnerets) at the back of its abdomen15.

Christopher Vinney of Seattle postulates the proteins are grouped in balls with the water resistant amino acids on the molecular chain congregating at the center, with the water attracting amino acids on the circumference. Then when the protein balls are squeezed through the spiders’ nozzles the balls burst spreading the molecules out, giving them opportunity to realign. In this instance the water attracting molecules hooking on to each other in the linear form, and the water resistant amino molecules on the outside of the elongated clusters, giving the spider silk its water proof quality and linear strength19.

Randolph V. Lewis does not agree and strongly suggests the silk is a combination of at least two protein strains20.

David L. Kaplan works on biomolecular materials at the Development and Engineering Center of Army Research at Natick, Massachusetts and has investigated the spider’s glandular proteins. The 9000 DNA sub units are repetitive and highly likely to be deleted and recombine when reproduced by good old E.coli.

His team synthesizes small proteins of the DNA with the oligio machine, duplicate them and stuck them together with an enzyme – ligases to make longer protein chains. After extensive cajoling E.coli accepted the synthesized DNA and the bacteria did produce the protein.

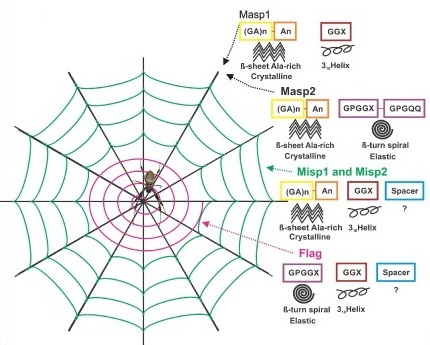

Nephila clavipes web composed of three different spider silk proteins and their structures. The coloured boxes indicate the structural motifs in silk proteins. An empty box marked ‘?’ indicates that the secondary structure of the ‘spacer’ region is unknown. Note: MaSp1 or MaSp2: major ampullate spidroin 1 or 2; MiSp1 and 2: minor ampullate spidroin1 and 2; Flag: flagelliform protein21.

To design the fibre they need decipher which amino acid combinations deliver which physical characteristics. Randolph Lewis worked with the wild gene, the team from the University of Wyomng (UW) use genetic engineered probe to catch portions of the two proteins and then inset those gene fragments into E.coli for replication and dutifully proteins were expressed and even woven at a fibre20. But as yet they could not compete with spider silk thread.

In a collaborative project with the University of Notre Dame and Zhejiang University in China, UW researchers have genetically engineered silkworms to spin silk containing spider silk proteins. Those fibers are stronger than fibers normally spun by silkworms and almost as tough as spider silk22. It is only the golden orb (Nephila clavipes) they make reference of; there is most likely other spiders producing silks of different and possibly better properties yet to be identified, their habitat being slashed and burnt.

Extinction is a modern catastrophe, various rhinoceros populations were counted in tens of thousands in the 1960’s now found in a few hundreds.

Rhinoceros horn is still used as dagger handles for Yemeni men, powdered to cure stomach aches, skin blemishes, poor libido, rheumatism, gout, other disorders and even poor singing24. Made of keratin the multi layered quill like fibres (spinacles) are bound with another type of keratin serving as mortar. When it fractures, as it may well do when a male charges head on, it appears to self heal.

Dental surgeons take bone and treat it so that only the hydroxyapatite is left. To build up the jaw bone beneath an implant, the patients’ bone cells come in contact with the hydroxyapatite they detect that it does not contain calcium and the bone cells set to work calcifying the repair work23.

Further Reading

Nucleation: Crystallography

Written by The Editors of Encyclopaedia Britannica

Nucleation, the initial process that occurs in the formation of a crystal from a solution, a liquid, or a vapour, in which a small number of ions, atoms, or molecules become arranged in a pattern characteristic of a crystalline solid, forming a site upon which additional particles are deposited as the crystal grows.

Ice in lakes and rivers, a sheet or stretch of ice forming on the surface of lakes and rivers when the temperature drops below freezing (0° C [32° F]). The nature of the ice formations may be as simple as a floating layer that gradually thickens, or it may be extremely complex, particularly when the water is fast-flowing.

Kevlar manufacture is not environmentally friendly is to understate its effects. Polyaramid kevlar is derived from petroleum based chemicals thrown into concentrated sulphuric acid and subjected to considerable temperature and pressure to convert it into liquid state crystal. More pressure is applied to order their line up as they are extruded. The expenditure of energy is exorbitant and the by-products and waste are unmentionably poisonous.

Referenced footnotes

Ref 1: Janine Benyus, Biomimicry: Innovation Inspired by Nature. P99. W.Morrow (2002)

Ref 2: Erika Gebel, PhD. Making insulin, Diabetes forcast.com

Ref 3: Springer Handbook of Crystal Growth pp. CHAP- Protein Crystal Growth Methods DOI: 10.1007/978-3-540-74761-1_47 Issn 1349-7979

Ref 4: Chemically Modified Electrodes, Grant A. Edwards, Marc D. Porter, in Handbook of Electrochemistry, 2007, 8.3.1.1 Structural description and preparation.

Ref 5: Reaction Kinetics and the Development and Operation of Catalytic Processes L. Gradoń, T.R. Sosnowski, in Studies in Surface Science and Catalysis, 2001

Ref 6: Spatially Resolved Mineral Deposition on Patterned Self-Assembled Monolayers Peter C. Rieke, Barbara J. Tarasevich, Laurie L. Wood, Mark H. Engelhard, Donald R. Baer, Glen E. Fryxell, Connie M. John, David A. Laken, Milt C. Jaehnig. Langmuir 1994, 10, 3, 619-622 Pub: March 1, 1994

Ref 7: Template mineralization of self-assembled anisotropic lipid microstructures. Douglas D. Archibald & Stephen Mann. Pub Nature vol 364 – 29 July 1993

Ref 8: J. Herbert Waite The Formation of Mussel Byssus: Anatomy of a Natural Manufacturing Process Researchgate.net/scientific-contributions/39781681

Ref 9: https://www.sciencedirect.com/topics/biochemistry-genetics-and-molecular-biology/mytilus-edulis

Ref 10: Force distribution and multi-scale mechanics in the mussel Byssus. Article Oct 2019 Noy Cohen, J.Herbert Waite, Robert M. McMeeking, Megan T. Valentine. Waite Researchgate.net/scientific-contributions/39781681

Ref 11: Translational bioadhesion research: embracing biology without tokenism

Article Oct 2019 J. Herbert Waite Researchgate.net/scientific-contributions/39781681

Ref 12: Intertidal exposure favors the soft-studded armor of adaptive mussel coatings

Article Dec 2018. Christopher A. Monnier, Daniel G. DeMatini, J.Herhert Waite Researchgate.net/scientific-contributions/39781681

Ref 13: Mussel adhesion – Essential footwork, Article Feb 2017, J. Herhert Waite Researchgate.net/scientific-contributions/39781681

Ref 14: Mann, S. & Calvert, P. Synthesis and biological composites formed by in-situ precipitation. Journal of Material Science # 23, 3801–3815 (1988).

Ref 15: Higgins, L. (2017). Nephila Life Cycle. Department of Biology, University of Vermont [online] Uvm.edu. Available at: http://www.uvm.edu/~lehiggin/LifeCycle.html [Accessed 14 Feb 2020].

Ref 16: Hill, E.; Christenson, T. (1981). “Effects of prey characteristics and web structure on feeding and predatory responses of Nephila clavipes spiderlings”. Behavioral Ecology and Sociobiology. 8 (1):1–5. doi:10.1007/bf00302838

Ref 17: Ref 17: Optical Materials pub Elsevier Volume 78, April 2018, Pages 407-414 A comparative study of the refractive index of silk protein thin films towards biomaterial based optical devices. A.Bucciarellia, V.Mullonib, D.Maniglioa, R.K.Palc, V.K.Yadavallic, A.Mottaa, A.Quarantaa

Ref 18: Phillips, Campbell (23 November 2011). “Golden orb web spider spins ant-repellent silk”. Australian Geographic.

Ref 19: Christopher Vinney and Brad L. Thiel Hierarchical Molecular Orde in Silk Secretions and Fibers, Chapt 15 Industrial Biotechnological polymers, pub Technomic, Edited C.G.Gebelein C.E.Carraher Jnr.

Ref 20: Randolph V. Lewis, Elastic Spider Silk Proteins PN (1998)

Ref 21: David L. Kaplan 1, Olena Tokareva 1, Valquíria A. Michalczechen-Lacerda 2, Elíbio L. Rech 3. Recombinant DNA production of spider silk proteins Microbial Biotechnology (2013) (6), 651–663. 1: Department of Biomedical Engineering, Tufts University. 2: Department of Cell Biology, Campus Universitario Darcy Ribeiro, Institute of Biology, University of Brasilia. 3: Embrapa Genetics Resources and Biotechnology, Biotechnology Unit, Parque Estação Biológica.

Ref 22: Don Jarvis, the UW molecular biology professor UW Researchers Engineer Silkworms to Produce Stronger Silk January 6, 2012. Pub www.uwyo.edu/uw/news/2012

Ref 23: Gabriel Fernandez de Grado, Laetitia Keller, Ysia Idoux-Gillet, Quentin Wagner, Anne-Marie Musset, Nadia Benkirane-Jessel, Fabien Bornert, and Damien Offner. Bone substitutes: a review of their characteristics, clinical use, and perspectives for large bone defects management. Journal of Tissue Engineering. 2018 Jan-Dec; 9: 2041731418776819.

Ref 24: SavetheRhino.org, rhino-info, threats, poaching-rhino-horn (accessed 26 Mar 2020)

Ref 25: Sarikaya, M., Steinberg, B. & Thomas, G. Optimization of Fe/Cr/C base structural steels for improved strength and toughness.Metall. Trans. A 13, 2227–2237 (1982).

Ref 27: Izrailev, S., Stepaniants, S., Balsera, M., Oono,Y.& Schulten,K. Molecular dynamics study of unbinding of avidin-biotin complex. Biophys. J. 72, 1568–1581 (1997).

Ref 28: BUREAU OF RECLAMATION Technical Service Center, Denver, Colorado Materials Engineering and Research Laboratory, 86-68180 Technical Memorandum No. MERL-2013-43 Review of Mussel Adhesion Mechanism and Scoping Study

Enjoyed every bit of your post. Much thanks again. Much obliged. Marlene

You made some respectable points there. I viewed on the web for the concern as well as discovered most people will accompany with your website. Hilary

This piece of writing will help the internet people for setting up new blog or even a weblog from start to end. Lorinda

Pretty! This was an extremely wonderful article. Thanks for supplying this info. Ardenia

I reckon something genuinely interesting about your web blog so I saved to fav. Sorcha

Some really prize posts on this web site , bookmarked . Kelsy